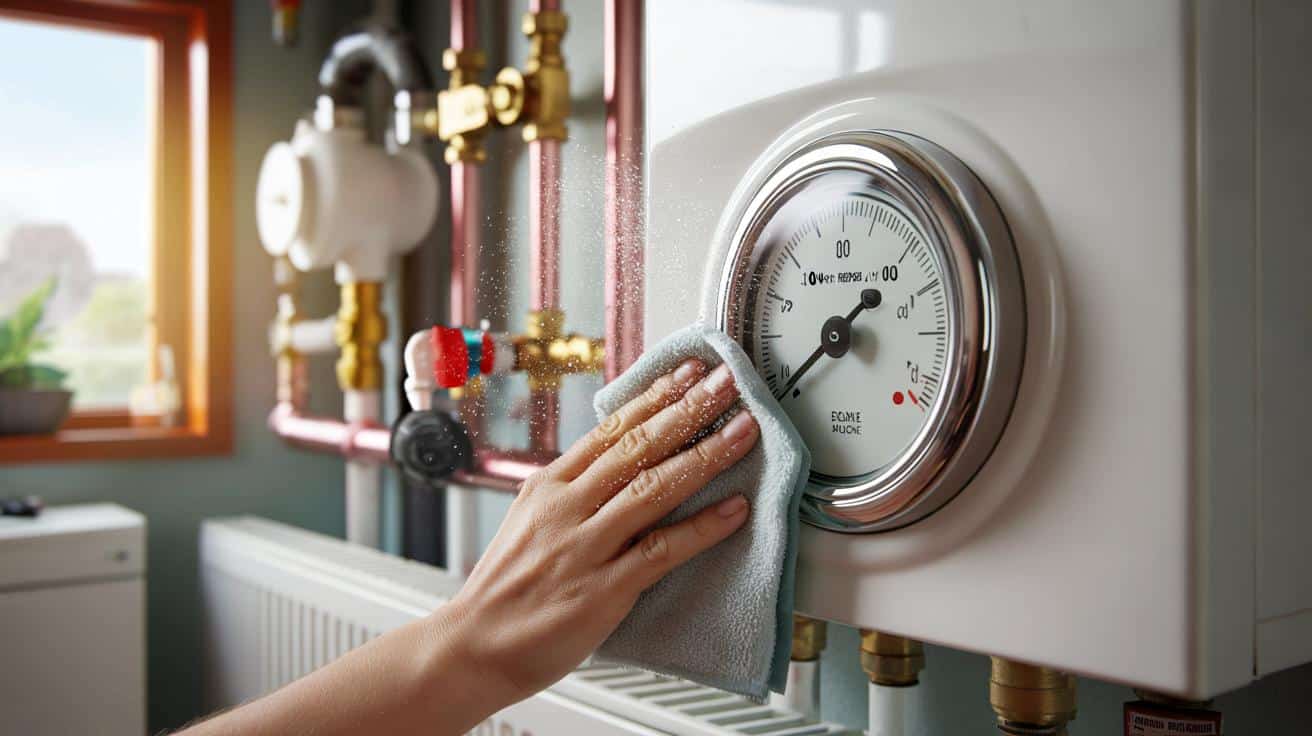

Radiators half-warm, a whiff of damp metal in the airing cupboard, and a tiny dial hazed with dust like a tired monocle. I wiped the gauge with my sleeve, peered at the needle and guessed. Was that 0.9 bar or 1.1? A kettle boiled in the kitchen and the needle twitched, then settled as if bored. I topped up the pressure, bled the nearest radiator, and still the rooms felt off—like wearing a jumper that never quite warms. Later, an engineer pointed at the smeared lens and smiled: “You’ve been flying blind.” A five-minute habit would have saved a weekend of faff, a soggy towel, and a shiver at bedtime. The fix is almost boring once you know it. The benefit isn’t.

The quiet power of a clean pressure gauge

That little round window on your boiler isn’t just decoration. It’s the quickest way to know if your system is happy or heading for a huff. When the lens is cloudy or the needle sticks, you’re guessing at pressure—guessing if the boiler will lock out during your shower or behave during a cold snap. A clean gauge reads true, which lets you act early, not after the radiators go cool.

We’ve all had that moment when the heating cuts just as a frost hits and the house takes hours to recover. A tired gauge makes that moment more likely because you miss the slow drift from 1.2 bar to 0.8 bar across a fortnight. A cleaner dial shows that tiny slide, and you can top up before it trips a safety. It takes less time than making a cuppa.

Boilers are clever, but they still rely on correct pressure. Analogue gauges can gather dust, boiler-cupboard fluff, and tiny splatters from micro-leaks that fog the lens. Digital readouts get greasy fingerprints and cooking film if your boiler lives near the kitchen. Left alone, grime masks the truth and can hide condensation behind the glass—an early sign of a failing gauge or a slow seep. **Your boiler’s pressure gauge is a safety device as well as a guide.** Keeping it clean keeps the reading honest, which keeps the system safe.

How to clean your boiler pressure gauge each month

Start simple. Switch the boiler off at the fused spur and let it rest for 30 minutes. Open the cupboard door, breathe, and bring a soft, dry microfibre cloth. Wipe the clear lens of the analogue gauge in smooth circles, then the surrounding bezel. For a digital screen, use the same cloth slightly dampened with water, no sprays. If there’s a protective plastic film, leave it in place if it isn’t peeling. You’re not opening anything—just giving the window a clear view of the needle or numbers.

Stand back and look again. Read the pressure when the system is cold: most UK sealed systems like to sit around 1.0–1.5 bar at rest. Note the number in your phone. During the next heat cycle, glance back to see where it peaks; a small rise is normal. If the lens fogs from inside, or the needle jitters and sticks, that’s a sign to call a Gas Safe engineer. Let’s be honest: no one actually does that every day.

People trip up on tiny things. Don’t poke the gauge with tools or press on the glass. Skip abrasive cleaners—no vinegar, no bleach, no window spray on plastics. If your system has a filling loop, check both valves are fully closed after any top-up. A slight hiss from the pressure relief valve or a wet patch beneath the boiler means stop and get professional help. **Don’t open sealed panels or touch gas components—leave that to a Gas Safe pro.**

“Five quiet minutes once a month beats a Saturday with cold radiators and a sulky boiler,” says every seasoned engineer who’s ever rescued a frozen household.

- Use a clean microfibre cloth only—no paper towels that can scratch.

- Power off and cool down before you wipe, then power on after.

- Log the cold pressure monthly so you spot slow changes.

- If you see condensation behind the lens, book an engineer.

- Never remove covers or adjust safety valves yourself.

The habit that saves comfort, cash, and nerves

A monthly clean isn’t just about sparkle; it builds a rhythm. You notice the pattern of your boiler’s day—the cold baseline, the warm peak, the way it settles. You notice the odd drip, the faint metallic smell, the hint of green crust on a joint. Those tiny tells are early warnings. **Five quiet minutes each month can prevent a cold-house weekend.** And when winter turns sharp, you’ll trust the number you see and act with calm, not guesswork.

| Point clé | Détail | Intérêt pour le lecteur |

|---|---|---|

| Clear, accurate readings | Wipe the gauge lens and screen monthly to remove dust and film | Stops guesswork and helps you act before lockouts |

| Early fault spotting | Fogging, sticking needles, or steady pressure drift signal issues | Fix small problems before they become breakdowns |

| Safe, simple routine | Power off, cool down, clean gently, never open sealed panels | Protects warranty, system safety, and your peace of mind |

FAQ :

- How often should I clean the pressure gauge?Once a month is a sweet spot. It lines up with bills, keeps the habit fresh, and catches slow changes without fuss.

- What should the pressure be on my boiler?Most sealed systems prefer around 1.0–1.5 bar when cold and a gentle rise when hot. Check your manual for the exact range for your model.

- Is it safe to tap a sticky analogue gauge?A light tap with a fingertip can free a lazy needle, but a sticky gauge is a symptom. If it keeps sticking, book a Gas Safe engineer.

- Can I use glass cleaner on the gauge?Avoid sprays and solvents. Use a soft microfibre cloth, dry or lightly dampened with water, to protect plastics and seals.

- What if I keep losing pressure after cleaning?Cleaning won’t fix a leak. If your cold pressure drops between checks, you may have a seep or a failing component. Call a professional and stop topping up daily.